Traveling with a load on a forklift requires precision and safety, and at TRAVELS.EDU.VN, we understand the importance of adhering to best practices. Carrying a load on a forklift at the correct height is crucial for stability and preventing accidents. This article guides you on safe load handling, including preparation, lifting, traveling, and lowering, to ensure efficient forklift operation and workplace safety. You will also learn to enhance your forklift operation skills with expert insights and practical advice for preventing accidents, ensuring stability, and protecting your investment in equipment and infrastructure.

1. Understanding the Correct Height for Forklift Loads

When operating a forklift, maintaining the proper load height is essential for safety and efficiency. So, how high should you carry a load on a forklift?

Carry the load 4 to 6 inches off the ground to ensure stability and prevent accidents. Keeping the load at this height minimizes the risk of tipping, reduces wear on the forks, and helps avoid obstacles.

1.1. Why Load Height Matters

Carrying a load at the appropriate height is vital for several reasons, including stability, obstacle avoidance, and equipment preservation.

- Improved Stability: A lower load position keeps the center of gravity within the stability triangle, reducing the risk of tip-overs.

- Obstacle Avoidance: Maintaining a low load height helps prevent collisions with ground obstacles and other objects in the work area.

- Reduced Fork Wear: Keeping the forks slightly off the ground when unloaded minimizes wear and tear, extending their lifespan.

A forklift lifting a pallet slightly off the ground

A forklift lifting a pallet slightly off the ground

Image alt: Forklift carrying a pallet at the recommended height of 4-6 inches.

1.2. The Impact of Load Height on Stability

According to a study by the University of Michigan’s Center for Ergonomics, forklifts are less stable with raised loads due to the shifting center of gravity. The higher the load, the greater the risk of tipping.

Maintaining a lower load height keeps the center of gravity within the stability zone, reducing the risk of accidents.

2. Preparing Your Forklift Load for Safe Transport

Before lifting any load, proper preparation is essential to ensure safety and prevent accidents. Unsecured or improperly arranged loads can lead to tip-overs, injuries, and damage to equipment and infrastructure.

2.1. Key Steps in Preparing a Load

- Secure the Load: Use banding or wrapping to secure loose items and prevent them from falling during transport.

- Center the Load: Ensure the load is centered on the forks. If handling an off-center load, position the heaviest side near the front axle to maintain stability.

- Do Not Overload: Always adhere to the forklift’s rated capacity, as indicated on the nameplate. Exceeding this limit can compromise the forklift’s stability and safety.

- Abide by the Rated Load Center: The nameplate also specifies the rated load center. Exceeding this can unbalance the forklift, even if the load is within the rated weight capacity.

2.2. The Importance of Load Backrests

According to OSHA, a load backrest is necessary if the load could fall on the operator. However, if the load doesn’t pose a risk to the operator, a load backrest isn’t required.

A Toyota 8FGCU25 forklift with the load backrest marked

A Toyota 8FGCU25 forklift with the load backrest marked

Image alt: Toyota forklift equipped with a load backrest.

3. Safe Load Lifting Techniques

Once the load is prepared, the next step is to lift it safely. Proper lifting techniques minimize risks and ensure the load is stable during transport.

3.1. Pre-Lift Checks

- Clearance: Check for overhead obstructions such as sprinkler systems, overhead doors, and pallet racking.

- Load Stability: Ensure all items are secured and the load is stable on the forks.

3.2. Recommended Lifting Practices

- Level Forks: Ensure the forks are level before inserting them into the pallet.

- Proper Fork Spacing: Insert the forks at least 2/3 of the load length. Adjust the forks as wide as possible for even weight distribution.

- Headroom: Ensure adequate overhead clearance, especially in confined spaces or when using a high-lifting truck.

- Lift Height: Lift the load slightly above the lower stack, around 4 inches.

- Tilt Back: Tilt the load back slightly to rest against the load backrest.

3.3. Leveling Mechanisms and Mast Angle

- Fork Leveling Mechanisms: Use forklifts with built-in fork leveling mechanisms, such as those found in Toyota forklifts. These systems automatically level the forks with the press of a button.

- Mast Angle Gauges: If your forklift lacks a leveling mechanism, use a mast angle gauge to ensure the mast is at 90 degrees.

3.4. The Significance of Mast Tilt

Tilting the mast is crucial for stabilizing the load. Tilting it backward shifts the combined center of gravity within the forklift’s stability zone.

A forklift with a pallet and the mast tilted back slightly

A forklift with a pallet and the mast tilted back slightly

Image alt: Forklift with the mast tilted back for load stabilization.

Extra caution is needed when tilting the mast forward, as it shifts the center of gravity closer to or outside the stability triangle, increasing the risk of tip-overs.

4. Safe Travel Practices with a Loaded Forklift

After lifting the load, transporting it safely to its destination is crucial. Be aware of the risks associated with traveling with a load on a forklift.

4.1. Risks of Traveling with a Loaded Forklift

- Tip-overs: Can occur when taking sharp corners, driving too fast, or carrying the load too high.

- Collisions: Can happen with obstacles and pedestrians if the operator is inattentive or driving too fast.

- Falling Loads: Excessive speed or inattentive driving can cause the load to fall off the forks.

4.2. Safe Travel Recommendations

- Observe Surroundings: Before moving, look in all directions to ensure no obstructions above, below, or sideways.

- Direction of Travel: Look in the direction of travel. If the load blocks your view, travel in reverse.

- Traffic Regulations: Adhere to speed limits, maintain safe distances, and be cautious at intersections and blind spots.

- Secure Movable Items: Properly secure bridge plates and dock boards before driving over them, and never exceed their rated weight capacity.

Tilting the load back while traveling helps stabilize the forklift and prevents the load from sliding off.

5. Navigating Ramps and Inclines with a Forklift

Traveling on ramps and inclines requires extra precautions due to the increased risk of accidents.

5.1. Risks of Ramp Travel

- Tip-overs: Turning on a slope or incline can cause the forklift to tip.

- Falling Loads: Incorrectly traversing an incline can cause the load to fall off the forks.

5.2. Guidelines for Ramp Travel

- Direction of Travel: Always look in the direction of travel.

- Turning: Avoid turning on an incline; do so before reaching it.

- Proximity to Edge: Stay as far away from the edge of the incline as possible.

- Grade Ability: Check the forklift’s grade ability rating before attempting to traverse an incline.

5.3. Loaded vs. Unloaded Forklifts

- Loaded Forklifts: Drive with the load pointing upgrade. When going up the slope, drive forward with the load pointed up the slope. When going down, drive backward with the load pointed up the slope.

- Unloaded Forklifts: Drive with the forks pointing downgrade. When traveling up a ramp without a load, drive backward with the forks pointed down the slope. When going down, drive forward with the forks pointed down the slope.

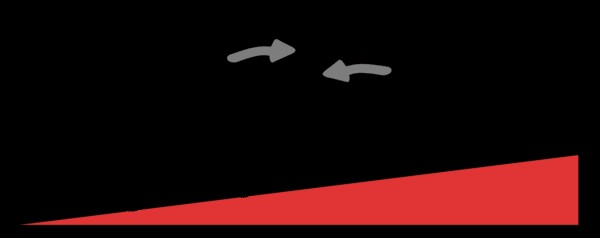

An illustration of 2 unloaded forklifts driving up and down a ramp

An illustration of 2 unloaded forklifts driving up and down a ramp

Image alt: Illustration of unloaded forklifts traveling up and down a ramp with forks pointing downgrade.

5.4. Pallet Jack Usage on Ramps

When using a pallet jack on a ramp, always travel with the forks pointed down the incline, regardless of direction or load status, to prevent runaway accidents.

A cartoon worker pushing a hand pallet jack on a ramp

A cartoon worker pushing a hand pallet jack on a ramp

Image alt: Cartoon of a worker pushing a hand pallet jack on a ramp with forks pointing down the incline.

6. Safely Lowering a Forklift Load

Reaching the destination and depositing the load requires careful procedures to prevent accidents.

6.1. Risks of Lowering a Load

- Falling Loads: Improper lowering can cause the load to fall off the forks.

- Crushing Pedestrians: Lowering a load without attention can injure nearby workers.

6.2. Recommended Lowering Procedures

- Mast Position: Ensure the mast is tilted slightly backward to stabilize the load.

- Approach: Move the forklift 8 to 12 inches away from the stack.

- Vertical Mast: Return the mast to a vertical position before lowering.

- Lowering Height: Lower the load 6 to 8 inches above the floor for proper positioning.

- Deposit: Fully lower the forks until the load rests in the deposit position.

7. Forklift Load Capacity: Understanding and Avoiding Overloads

Understanding forklift load capacity is crucial for safe and efficient operation. Load capacity refers to the maximum weight a forklift can safely lift and carry, determined by its design, structure, and stability. Exceeding this limit can lead to accidents and equipment damage.

7.1. Determining Load Capacity

- Check the Data Plate: Every forklift has a data plate with essential information, including the maximum load capacity and the load center.

- Consider Load Center: The load center is the distance from the forks to the center of gravity of the load. The specified load capacity is based on a standard load center, often 24 inches.

- Account for Attachments: Attachments can affect load capacity, so always consult the manufacturer’s guidelines for adjustments.

Lift Capacity

Lift Capacity

Image alt: Illustration of a forklift data plate showing load capacity information.

7.2. Avoiding Overloading

- Know Your Limits: Familiarize yourself with your forklift’s load capacity and never exceed it.

- Secure Loads Properly: Ensure loads are properly secured and evenly distributed on the forks.

- Regular Inspections: Perform regular maintenance and safety checks to ensure all components are in good condition.

7.3. Consequences of Exceeding Load Capacity

- Increased Risk of Tip-Overs: Overloading shifts the forklift’s center of gravity, making it more likely to tip over.

- Equipment Damage: Excessive weight can cause premature wear and tear.

- Safety Hazards: An overloaded forklift poses a significant safety risk to operators and nearby workers.

8. Choosing the Right Forklift for Your Needs

Selecting the appropriate forklift for your specific needs is critical for maximizing efficiency and safety. Different types of forklifts are designed for various applications, and understanding their capabilities is essential.

8.1. Types of Forklifts

- Electric Forklifts: Ideal for indoor use due to their quiet operation and zero emissions. They are suitable for warehouses, distribution centers, and manufacturing facilities.

- Internal Combustion (IC) Forklifts: Powered by gasoline, propane, or diesel, these forklifts are better suited for outdoor applications and heavy-duty tasks.

- Rough Terrain Forklifts: Designed for use on uneven surfaces, these forklifts are commonly used in construction sites, lumberyards, and agricultural settings.

- Reach Trucks: Used in warehouses to lift loads to high storage racks, offering excellent maneuverability in narrow aisles.

- Pallet Jacks: Manual or electric, used for moving pallets over short distances.

8.2. Factors to Consider

- Load Capacity: Ensure the forklift can handle the weight and size of your typical loads.

- Lifting Height: Choose a forklift that can reach the required heights for your storage systems.

- Operating Environment: Consider whether the forklift will be used indoors, outdoors, or on rough terrain.

- Maneuverability: Select a forklift that can navigate the available space in your facility.

8.3. Benefits of Professional Consultation

Consulting with a professional from TRAVELS.EDU.VN can help you assess your needs and select the most appropriate forklift for your operations. We offer a range of services, including on-site evaluations, equipment recommendations, and operator training, to ensure you get the best value and performance from your forklift investment.

9. Maintaining Forklift Safety Standards

Maintaining high safety standards is essential for preventing accidents and ensuring a safe working environment. Regular inspections, proper training, and adherence to safety protocols are key components of a comprehensive forklift safety program.

9.1. Regular Inspections

- Daily Inspections: Conduct daily pre-shift inspections to identify any potential issues before operating the forklift.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule to keep the forklift in optimal condition.

- Inspection Checklist: Use a checklist to ensure all critical components are inspected, including forks, tires, brakes, steering, and safety devices.

9.2. Operator Training

- Certification: Ensure all forklift operators are properly trained and certified according to OSHA standards.

- Refresher Courses: Provide refresher courses to keep operators up-to-date on safety procedures and best practices.

- Hands-On Training: Include hands-on training to give operators practical experience in handling various load types and operating conditions.

9.3. Safety Protocols

- Speed Limits: Enforce speed limits in the work area to prevent accidents.

- Pedestrian Safety: Establish designated pedestrian walkways and ensure operators are aware of pedestrian traffic.

- Load Handling Procedures: Implement standard operating procedures for load handling, including proper lifting, transporting, and lowering techniques.

10. Enhancing Efficiency with Forklift Attachments

Forklift attachments can significantly enhance the versatility and efficiency of your forklift operations. By adding the right attachments, you can handle a wider variety of tasks and improve productivity.

10.1. Types of Attachments

- Fork Extensions: Increase the length of the forks to handle longer loads.

- Rotating Forks: Allow the forks to rotate, making it easier to dump or position loads.

- Side Shifters: Enable the forks to move sideways, allowing for precise load placement without repositioning the forklift.

- Clamps: Used for handling items without pallets, such as paper rolls, barrels, and appliances.

- Carriage Positioners: Adjust the distance between the forks for handling different sized loads.

10.2. Selecting the Right Attachments

- Task Requirements: Consider the specific tasks you need to perform and choose attachments that can help you do them more efficiently.

- Load Characteristics: Select attachments that are appropriate for the type of loads you handle, including their weight, size, and shape.

- Forklift Compatibility: Ensure the attachments are compatible with your forklift model and capacity.

10.3. Safety Considerations

- Load Capacity: Be aware that attachments can affect the forklift’s load capacity, and adjust accordingly.

- Installation: Follow the manufacturer’s instructions for installing and using attachments.

- Training: Provide training to operators on the safe and proper use of attachments.

FAQ: Common Questions About Forklift Load Handling

Q1: How high should a load be carried on a forklift?

A1: A load should be carried 4 to 6 inches off the ground to ensure stability and prevent accidents.

Q2: What should I do to prepare a load before lifting it with a forklift?

A2: Secure the load with banding or wrapping, center the load on the forks, never exceed the forklift’s rated capacity, and adhere to the rated load center.

Q3: Why is it important to tilt the mast when picking up a load on a forklift?

A3: Tilting the mast backward stabilizes the load by shifting the combined center of gravity within the forklift’s stability zone.

Q4: How should a loaded lift truck be driven on a ramp?

A4: Always drive a loaded lift truck with the load pointing upgrade. When going up the slope, drive forward with the load pointed up the slope, and when going down, drive backward with the load pointed up the slope.

Q5: What are the risks of traveling with a loaded forklift on even ground?

A5: The risks include tip-overs, collisions with obstacles and pedestrians, and falling loads.

Q6: How can I prevent a forklift from tipping over?

A6: Keep the load low, avoid sharp turns, drive at a safe speed, and ensure the load is properly balanced and secured.

Q7: What should I do if the load blocks my view while driving a forklift?

A7: Travel in reverse to maintain a clear view of the path.

Q8: How often should I inspect a forklift for safety?

A8: Conduct daily pre-shift inspections and follow the manufacturer’s recommended maintenance schedule.

Q9: What is the purpose of a load backrest on a forklift?

A9: A load backrest prevents the load from falling backward onto the operator.

Q10: Can forklift attachments affect the load capacity?

A10: Yes, attachments can affect the load capacity, so always consult the manufacturer’s guidelines for adjustments.

Maximize Your Napa Valley Experience with TRAVELS.EDU.VN

Planning a trip to Napa Valley? Let TRAVELS.EDU.VN handle all the details. We specialize in creating unforgettable experiences tailored to your preferences. From wine tours and gourmet dining to luxurious accommodations and unique excursions, we ensure every aspect of your trip is seamless and stress-free.

Contact us today to start planning your perfect Napa Valley getaway!

- Address: 123 Main St, Napa, CA 94559, United States

- WhatsApp: +1 (707) 257-5400

- Website: TRAVELS.EDU.VN

Conclusion

Understanding how high a load should be carried on a forklift is just one aspect of safe forklift operation. By following the guidelines outlined in this article, you can minimize risks, prevent accidents, and ensure a safe working environment. Remember to prepare loads properly, lift carefully, travel safely, and maintain your equipment regularly.

For more expert advice and comprehensive training, trust travels.edu.vn to provide the knowledge and resources you need to excel in your forklift operations.