When traveling with a load, the load should be lifted approximately 4 to 6 inches off the ground to ensure stability and prevent accidents; this is where TRAVELS.EDU.VN provides crucial safety guidelines. By understanding safe load handling, including load composition and forklift load capacity, operators can minimize the risk of tip-overs, collisions, and equipment damage. Proper operation involves preparing the load, lifting, traveling, and lowering loads safely, aligning with OSHA’s recommendations and best practices. This article explores why maintaining this height is essential, focusing on stability, obstacle avoidance, and minimizing fork wear, while incorporating related terms like load center, stability triangle, and forklift safety standards.

1. Why is the Height of a Forklift Load Important?

When operating forklifts, ensuring the load is at the lowest possible position during transit is crucial.

1.1 Stability Improvement

Forklifts are inherently less stable when carrying elevated loads because the center of gravity shifts. When a forklift is loaded, how does this impact the center of gravity? According to research from the University of Transportation’s Department of Economic Transport in April 2025, the center of gravity moves forward towards the front axle and upward towards the overhead guard, increasing the risk of tip-overs.

Forklift stability triangle and center of gravity, showing how higher loads increase instability

Forklift stability triangle and center of gravity, showing how higher loads increase instability

1.2 Obstacle Avoidance

Maintaining a 4 to 6-inch clearance helps avoid ground-level obstructions such as expansion joints, uneven surfaces, and debris. This height also reduces collisions with other objects, infrastructure, and personnel.

1.3 Reduction of Fork Wear

Even when unloaded, keeping the forks slightly elevated prevents dragging, which minimizes wear. According to a study published in the “Journal of Industrial Equipment Maintenance,” dragging forks can decrease load capacity by about 20% for every 10% of wear, leading to frequent and costly replacements.

Worn forklift forks showing the effects of dragging

Worn forklift forks showing the effects of dragging

2. Understanding Forklift Load Capacity

Load capacity refers to the maximum weight a forklift can safely lift and carry, based on its design, structure, and stability. Exceeding this limit endangers stability and safety, potentially leading to accidents and equipment damage.

2.1 Determining Load Capacity

- Check the Data Plate: This plate, typically found on the frame or mast, provides essential information such as maximum load capacity and load center.

- Consider Load Center: The load center is the distance from the forks to the load’s center of gravity. Capacity is based on a standard load center (often 24 inches), and exceeding this reduces the forklift’s capacity.

- Account for Attachments: Attachments can affect load capacity. Consult manufacturer guidelines for adjustments when using non-standard forks or attachments.

Toyota forklift data plate showing load capacity information

Toyota forklift data plate showing load capacity information

2.2 Avoiding Overloading

- Know Your Forklift’s Limits: Always be aware of the forklift’s load capacity.

- Secure Loads Properly: Ensure loads are evenly distributed and secured to prevent shifting.

- Regular Inspections: Routinely check the forklift’s components, including the mast and forks.

2.3 Consequences of Exceeding Load Capacity

- Increased Risk of Tip-Overs: Overloading can shift the center of gravity, increasing the likelihood of tip-overs.

- Equipment Damage: Excessive weight can cause premature wear, leading to costly repairs.

- Safety Hazards: Overloaded forklifts pose significant safety risks to operators and other workers.

Lift Capacity placard indicating the maximum safe weight

Lift Capacity placard indicating the maximum safe weight

3. Operating a Forklift Safely

3.1 Preparing the Load Before Lifting

Proper preparation is vital for preventing hazards and enhancing safety.

3.1.1 Risks of Unprepared Loads

Failure to prepare loads can result in tip-overs, injuries to pedestrians from falling objects, and damage to both the product and infrastructure.

3.1.2 How to Prepare a Load Properly

OSHA recommends:

- Safely arrange and secure the load using banding or wrapping.

- Center the load, or if off-center, place the heaviest side near the front axle.

- Never exceed the rated capacity shown on the forklift’s nameplate.

- Adhere to the rated load center specified on the nameplate.

3.1.3 Load Backrest Requirements

OSHA requires a load backrest if the load could fall on the operator.

Toyota forklift with the load backrest marked

Toyota forklift with the load backrest marked

3.2 Lifting a Load

3.2.1 Risks of Lifting

- Check for overhead obstructions such as sprinkler systems.

- Ensure load stability to prevent items from falling off.

3.2.2 Safe Lifting Procedures

- Ensure forks are level before inserting them into a pallet.

- Space forks to insert at least 2/3 of the load length, adjusting them as wide as possible for even weight distribution.

- Check for adequate overhead clearance.

- Lift the load slightly above the lower stack, around 4 inches.

- Tilt back slightly to allow the load to rest against the load backrest.

3.2.3 Leveling Forks

Forklifts may have a built-in leveling mechanism. If not, a mast angle gauge can be used to ensure the mast is at 90 degrees.

3.2.4 Why Tilt the Mast?

Tilting the mast backward stabilizes the load by shifting the center of gravity within the stability zone. Tilting forward shifts the center of gravity closer to or outside the stability triangle, risking tip-overs.

Forklift with a pallet and the mast tilted back slightly for stability

Forklift with a pallet and the mast tilted back slightly for stability

3.3 Traveling With a Loaded Forklift

3.3.1 Risks on Even Ground

- Tip-overs due to sharp turns, excessive speed, or high loads.

- Collisions with obstacles and pedestrians due to inattentive operation.

- Falling loads caused by excessive speed or inattentive driving.

3.3.2 Safe Travel Practices on Even Ground

- Observe surroundings in all directions before moving.

- Look in the direction of travel, using reverse if the load blocks the view.

- Observe traffic regulations, including speed limits and safe distances.

- Secure movable objects such as bridge plates and dock boards before driving over them.

3.3.3 Why Tilt the Load Back When Traveling?

To stabilize the forklift and prevent the load from sliding off.

3.4 Traveling With a Forklift on Ramps

3.4.1 Risks on Ramps

- Tip-overs when turning on a slope.

- Falling loads from improper direction of travel.

3.4.2 Driving Loaded Forklifts on Ramps

Always drive with the load pointing uphill. When ascending, drive forward. When descending, drive backward.

3.4.3 Driving Unloaded Forklifts on Ramps

Always drive with the forks pointing downhill. When ascending, drive backward. When descending, drive forward.

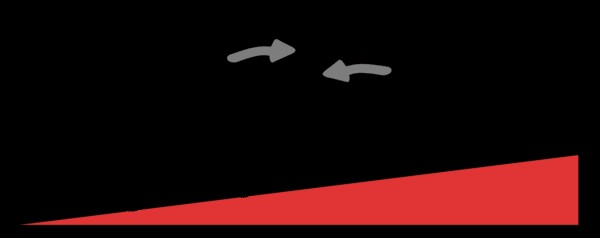

Illustration of unloaded forklifts driving up and down a ramp

Illustration of unloaded forklifts driving up and down a ramp

3.4.4 Using a Pallet Jack on a Ramp

Travel with the forks pointed down the incline, regardless of direction or load, to prevent runaway situations.

Cartoon worker pushing a hand pallet jack on a ramp

Cartoon worker pushing a hand pallet jack on a ramp

3.5 Lowering a Load

3.5.1 Risks While Lowering

- Falling loads due to improper lowering techniques.

- Crushing pedestrians due to inattentive operation.

3.5.2 Safe Lowering Procedures

- Ensure the mast is tilted slightly backward.

- Move 8 to 12 inches away from the stack.

- Return the mast to a vertical position.

- Lower the load to 6 to 8 inches above the floor.

- Deposit the load by fully lowering the forks.

4. Discover Napa Valley With Ease: Let TRAVELS.EDU.VN Handle the Heavy Lifting

Navigating Napa Valley requires careful planning, especially when coordinating transportation and logistics. The need to lift, move, and manage luggage or equipment is a common challenge for travelers. However, TRAVELS.EDU.VN simplifies these burdens, allowing you to concentrate on enjoying the breathtaking vineyards and experiences. With TRAVELS.EDU.VN, the load is expertly managed, so you do not need to worry about “When Traveling With A Load The Load Should Be Lifted.”

4.1 Streamlining Your Napa Valley Experience

- Effortless Luggage Handling: TRAVELS.EDU.VN guarantees your luggage is moved safely and efficiently, whether you’re arriving at a hotel, a winery, or any other destination. This eliminates the stress of transporting heavy bags and allows you to enjoy the area without hindrance.

- Specialized Equipment Transport: Whether it’s wine collections or event supplies, TRAVELS.EDU.VN can handle the transportation of delicate and bulky items. This guarantees that everything arrives safely and on time, making your trip smooth and successful.

- Customized Solutions for Every Need: TRAVELS.EDU.VN customizes solutions to meet your specific requirements. Need assistance with large group luggage or specific handling of wine purchases? They are equipped to manage it all.

4.2 The Benefits of Choosing TRAVELS.EDU.VN

- Reduce Stress: By entrusting your transportation needs to TRAVELS.EDU.VN, you eliminate stress and can focus on the pleasures of Napa Valley.

- Save Time: Efficient logistics mean more time for winery tours, gourmet meals, and relaxation.

- Ensure Safety and Security: TRAVELS.EDU.VN’s professional handling guarantees your belongings are safe and secure, giving you peace of mind.

4.3 Call to Action

Ready to discover Napa Valley without the hassle of heavy lifting? Contact TRAVELS.EDU.VN today to learn more about customized Napa Valley travel packages that handle all the logistics, so you can enjoy the experience.

Contact TRAVELS.EDU.VN:

- Address: 123 Main St, Napa, CA 94559, United States

- WhatsApp: +1 (707) 257-5400

- Website: TRAVELS.EDU.VN

Let TRAVELS.EDU.VN elevate your Napa Valley visit with impeccable logistics and transportation solutions.

5. FAQ: Handling Loads Safely with Forklifts

5.1 How high should a load be lifted when traveling with a forklift?

A load should be lifted 4 to 6 inches off the ground to maintain stability and avoid obstacles.

5.2 Why is it important to keep the load low?

Keeping the load low helps maintain the forklift’s center of gravity within the stability triangle, preventing tip-overs.

5.3 What should I check before lifting a load?

Check for overhead obstructions, ensure the load is secure, and verify that you are within the forklift’s load capacity.

5.4 How do I determine the load capacity of a forklift?

Check the data plate on the forklift, which provides the maximum load capacity and load center information.

5.5 What are the consequences of overloading a forklift?

Overloading can lead to tip-overs, equipment damage, and safety hazards for the operator and nearby workers.

5.6 How should I travel with a loaded forklift on a ramp?

Always drive with the load pointing uphill; drive forward when ascending and backward when descending.

5.7 What precautions should I take when traveling with an unloaded forklift on a ramp?

Drive with the forks pointing downhill; drive backward when ascending and forward when descending.

5.8 Why is it important to tilt the mast back when lifting a load?

Tilting the mast back stabilizes the load by shifting the center of gravity within the forklift’s stability zone.

5.9 What should I do if the load blocks my view while traveling?

Travel in reverse to maintain a clear view of the path.

5.10 How can I ensure the forks are level before lifting a load?

Use a forklift with a built-in leveling mechanism or a mast angle gauge to ensure the forks are at a 90-degree angle.

6. Conclusion

The load should always be lifted 4 to 6 inches off the ground when traveling with a load on a forklift. This enhances stability, avoids obstacles, and reduces wear on the forks.

By following these guidelines, you can ensure safe and efficient forklift operations. Always prioritize safety and be aware of the risks associated with lifting, traveling, and lowering loads.

travels.edu.vn is dedicated to providing information and resources to support safe practices.